| Planetary

Gearheads |

Spur Gearheads | ||

|

♦ ♦ ♦ ♦ ♦ |

V Series (IG-13V, 16V and 22V) planetary gearheads offer higher torque thanks to optimum design and are of

simple construction realized by sintered components. R Series (IG-16R and 22R) planetary gearheads have very

small backlash thanks to highly precise machining and assembly. Higher torque transmittable. Efficiency: 81% per stage Input-output position: Same center Input/output rotating direction: Same |

♦ ♦ ♦ ♦ ♦ ♦ |

Centered around RB-35 Series, the world standard, selection can be made from a wide range of products according

to applications such as size and torque. RB-35V Series has been developed on the concept of "long life and continuous run" and can be combined with brushless motors. The product lineup is enriched by the quiet type RB-35C employing a helical gear at the first stage and RB-35P most suitable for intermittent run. Small torque but thinner and quieter design is possible. Efficiency: 90% per stage Input-output position: Same center or different center Input/output rotating direction: Varies depending on number of stages |

|

|

|

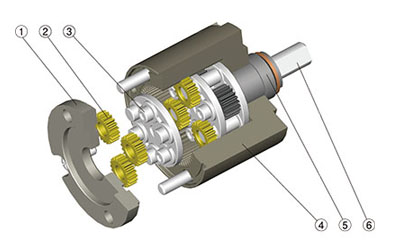

Planetary Gearhead (1) Bottom plate (2) Planetary gear (3) Carrier (4) Internal gear (5) Bearing (6) Output shaft |

|

|

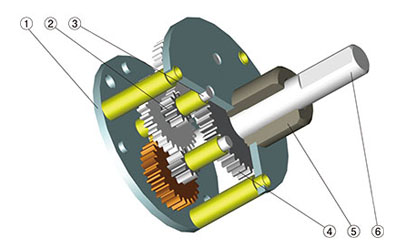

Spur Gearhead (1) Bottom plate (2) Small gear (3) Shaft (4) Large gear (5) Bearing (6) Output shaft |

|

♦ Gearheads

A gearhead mechanism capable of increasing torque by reducing the motor speed. An approximate value can be calculated using the following equation. The reduction ratio has been established for each model. Please see the pages of products.

♦ Gear efficiency

Gearheads have mechanical loss (gear meshing, bearing friction, etc.). Generally, for each meshing of one stage, an efficiency of 81% for planetary gears and 90% for spur gears is used in calculation. The gear efficiency, however, varies largely depending on such factors as motor torque and speed therefore is presented as a reference value. When used at a lower torque, the efficiency will drop significantly.

<An example of calculation of efficiency>

·Spur gear 3-stage meshing

Efficiency(η)=0.9× 0.9× 0.9= 0.73(73%)

·Planetary gear 2-stage meshing

Efficiency(η)=0.81× 0.81= 0.66(66%)

♦ Backlash

The amount of gearheads backlash depends on a play required for smooth meshing and a play between the shaft and the bearing. Note, however, it increases under load due to elastic deformation.

Reference image

A gearhead mechanism capable of increasing torque by reducing the motor speed. An approximate value can be calculated using the following equation. The reduction ratio has been established for each model. Please see the pages of products.

♦ Gear efficiency

Gearheads have mechanical loss (gear meshing, bearing friction, etc.). Generally, for each meshing of one stage, an efficiency of 81% for planetary gears and 90% for spur gears is used in calculation. The gear efficiency, however, varies largely depending on such factors as motor torque and speed therefore is presented as a reference value. When used at a lower torque, the efficiency will drop significantly.

<An example of calculation of efficiency>

·Spur gear 3-stage meshing

Efficiency(η)=0.9× 0.9× 0.9= 0.73(73%)

·Planetary gear 2-stage meshing

Efficiency(η)=0.81× 0.81= 0.66(66%)

♦ Backlash

The amount of gearheads backlash depends on a play required for smooth meshing and a play between the shaft and the bearing. Note, however, it increases under load due to elastic deformation.